Advanced Manufacturing

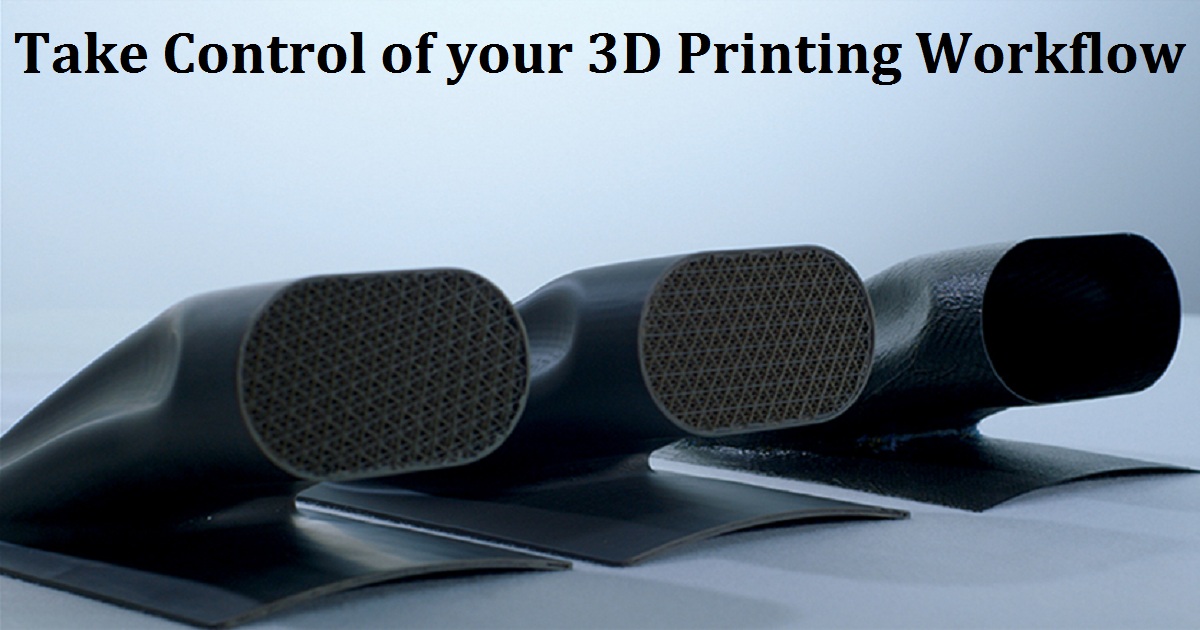

With 3D Printing there is no easy print button. Learn from industry experts like Google on how they have optimized their 3D printing workflow. During the webinar, our experts will: Discuss the challenges of preparing a part for 3D printing, Explain how designing for 3D Printing differs from traditional manufacturing, Demonstrate a 3D printing data preparation workflow.

Watch Now

DSIAC

Additive manufacturing powders supplied by the manufacturer are gas atomized and supplied without post treatment. By including a pre-processing treatment prior to AM, the powder can be modified to improve the mechanical properties of the final build via a reduction in internal powder porosity and grain size refinement.

Watch Now

Tekla

The new Tekla PowerFab is a complete steel fabrication management information system. Created specifically for steel fabricators, this powerful software suite truly connects estimating, production, project management and purchasing operations.

Watch Now

With the electric vehicle market poised to grow sixfold over the remainder of the decade, manufacturers and their key suppliers are rushing into the market to get in on the boom. According to Accenture, established companies risk losing 30 percent of their revenue to competitors by 2035. Our upcoming webinar reveals how one leading Tier 1 automotive supplier is using low code to keep in front of its cutthroat competition.

The Schaeffler Group, a leading global supplier to the automotive and industrial sectors, continues to thrive in a crowded marketplace 75 years after its founding by incessantly seeking out the best tools for maximizing its agility and efficiency. In our webinar, Jakob John, Schaeffler digital process transformation & demand coordination, will share how Schaeffler grew their business and empowered their workforce by adopting a low-code application development platform.

Watch Now