Protolabs

In this webinar, you'll see the quality measures that your parts undergo as we trace their digital path from CAD analysis to the production floor to in-process and post-process quality reporting.

Watch Now

dotData

The smart factory is much more than just an automated facility. It is a fully connected digital production system that has a constant stream of data coming from sources including production machinery, pick-and-place equipment, machine vision systems for inspection, robots of different types, and various sensors.This 60-minute Webinar from the editors of Tech Briefs highlights the components and technologies that comprise the smart factory and helps you determine which ones you need and how to control them. You’ll also learn how implementing a smart factory can increase value and other benefits for your manufacturing facility.

Watch Now

Advanced Manufacturing

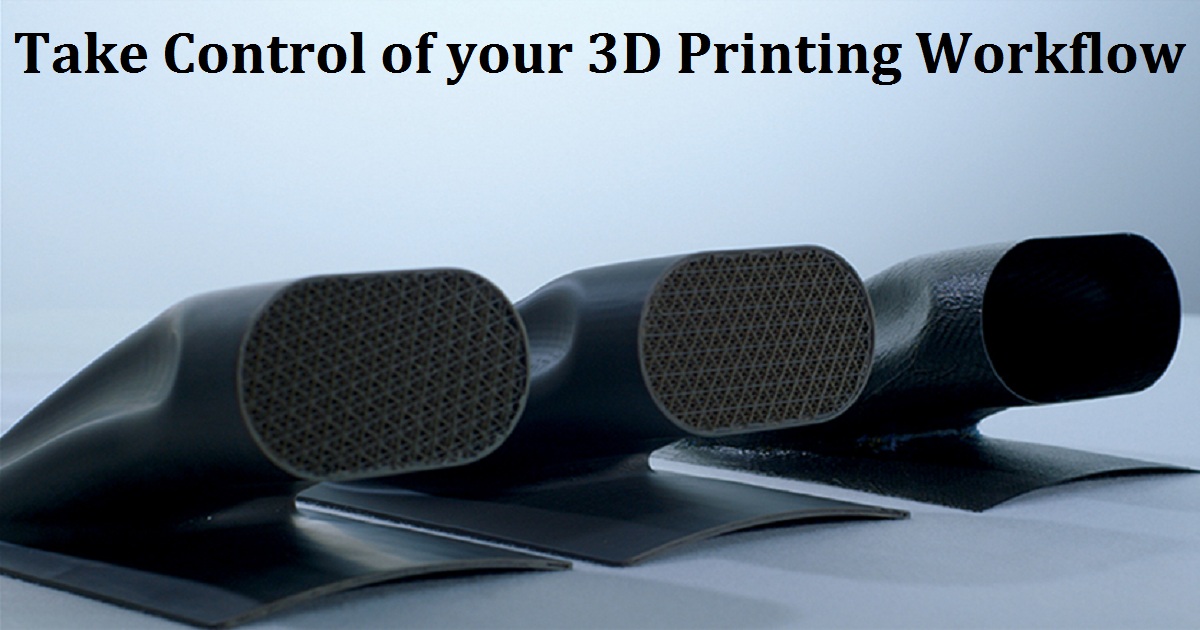

With 3D Printing there is no easy print button. Learn from industry experts like Google on how they have optimized their 3D printing workflow. During the webinar, our experts will: Discuss the challenges of preparing a part for 3D printing, Explain how designing for 3D Printing differs from traditional manufacturing, Demonstrate a 3D printing data preparation workflow.

Watch Now

BigRep

Jigs and fixtures are a mainstay of manufacturing and make production and assembly processes simpler and more reliable, reducing lead times and improving worker safety. Ford Motor Company has compared 3D-printed jigs and fixtures to conventional machining, finding they take less time and cost a fraction to produce.

Watch Now