Stratasys

Learn how to justify the cost of a 3D printer with information that gives decision makers clear, measurable metrics on the investment’s return. Listen in this webinar as industry expert Todd Grimm explains the key strategies of Substitution, Augmentation and Extension using industry examples.

Watch Now

IndustryWeek

In manufacturing, four factors - speed, agility, quality, and reliability - typically decide winners from losers. But most of today’s plants are missing the secret to improving these areas: data. In fact, only a fraction of all data generated in manufacturing plants ever gets analyzed for insights, with little of that in real time.

Watch Now

BigRep

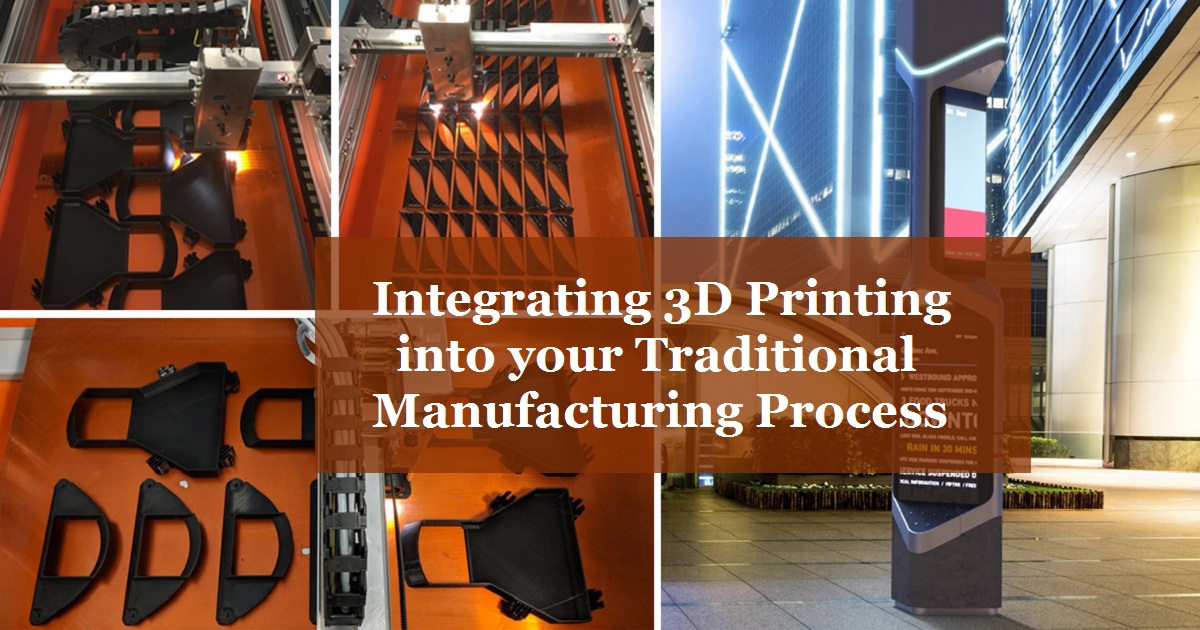

Additive manufacturing is becoming more and more integrated into the design and production environment, working in tandem with traditional manufacturing processes and coexisting on the manufacturing floor. Boyce Technologies, one of the leading manufacturers of security and communication equipment, rely on additive to create not only prototypes but also for end use parts, molds for vacuum forming and more.

Watch Now

BigRep

Jigs and fixtures are a mainstay of manufacturing and make production and assembly processes simpler and more reliable, reducing lead times and improving worker safety. Ford Motor Company has compared 3D-printed jigs and fixtures to conventional machining, finding they take less time and cost a fraction to produce.

Watch Now