Unlock your productivity - Renishaw on multi-laser additive manufacturing

Renishaw | April 30, 2018

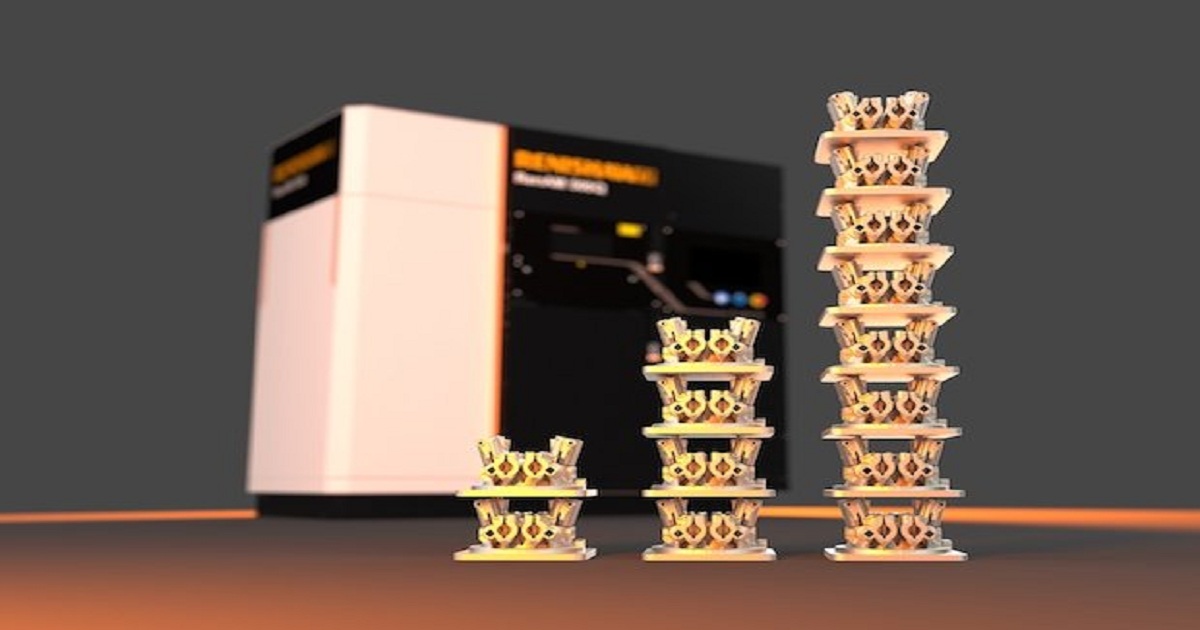

Two heads are better than one when it comes to creativity, but are four lasers better than one when it comes to metal additive manufacturing? The evidence speaks for itself; the new Renishaw RenAM 500Q four-laser system is expected to significantly improve productivity in the most commonly used machine platform size.

By speeding up the process by up to four times, Renishaw expects the RenAM 500Q to broaden the market appeal of metal additive manufacturing into applications that are presently uneconomic, and potentially into new industries that have yet to embrace AM in production applications.

The new four-laser system improves productivity up to four times without increasing platform size. Larger systems face additional challenges including increased material inventory, mechanical handling of heavier substrates, shielding gas efficiency over a larger working area and the inevitable higher capital cost and factory footprint of larger systems. For larger parts, these compromises must be accepted, but for a broader appeal, mid-sized machines tick more boxes and are presently mostly hampered by a lack of productivity due to a limited number of lasers.