The best and worst case for UK supply chains affected by the coronavirus

The Manufacturer | February 25, 2020

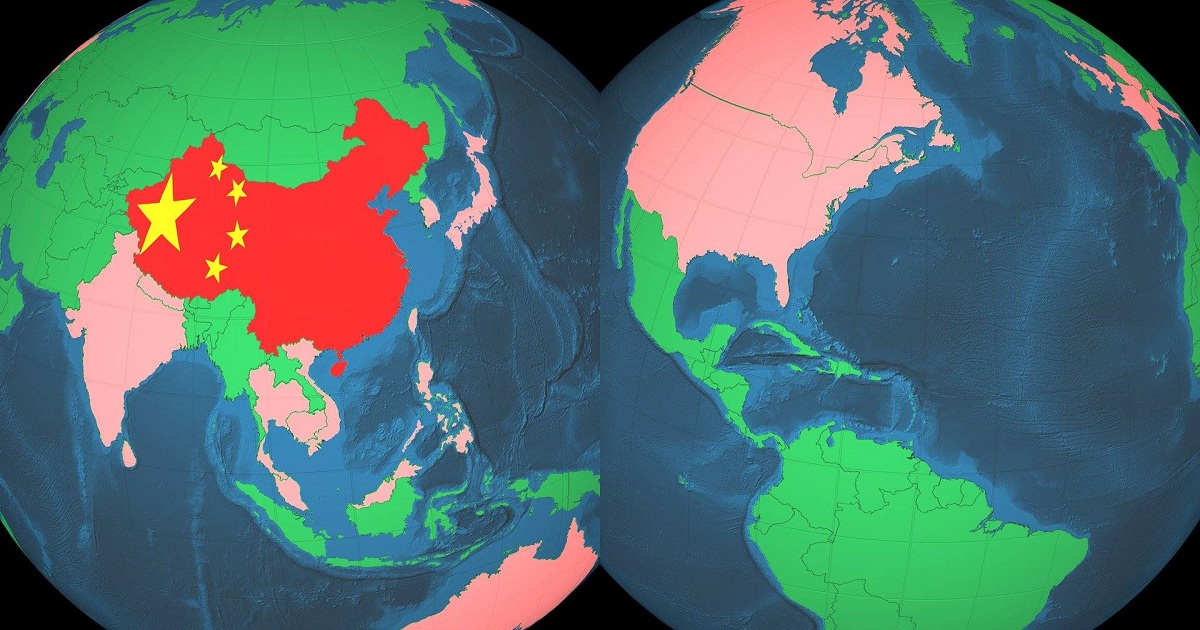

Manufacturing supply chains could face “months” of disruption, as factories in China struggle to reopen in the aftermath of the coronavirus outbreak which has crippled parts of the country’s economy. Manufacturing plants in China that produce smartphones, children’s toys and more complex components for automotive industry, stalled production because they stopped receiving materials necessary to build their products – which in turn affects the ability of UK manufacturer’s reliant on Chinese imports to meet customer demands. It is estimated that some 60 million people have been affected by travel restrictions within China, creating a shortage of manufacturing workers who are prevented from using public transport. Around 55 companies in Shanghai said last week that their global operations had been affected, with 78% saying they lacked enough staff to run production lines, according to the American Chamber of Commerce.