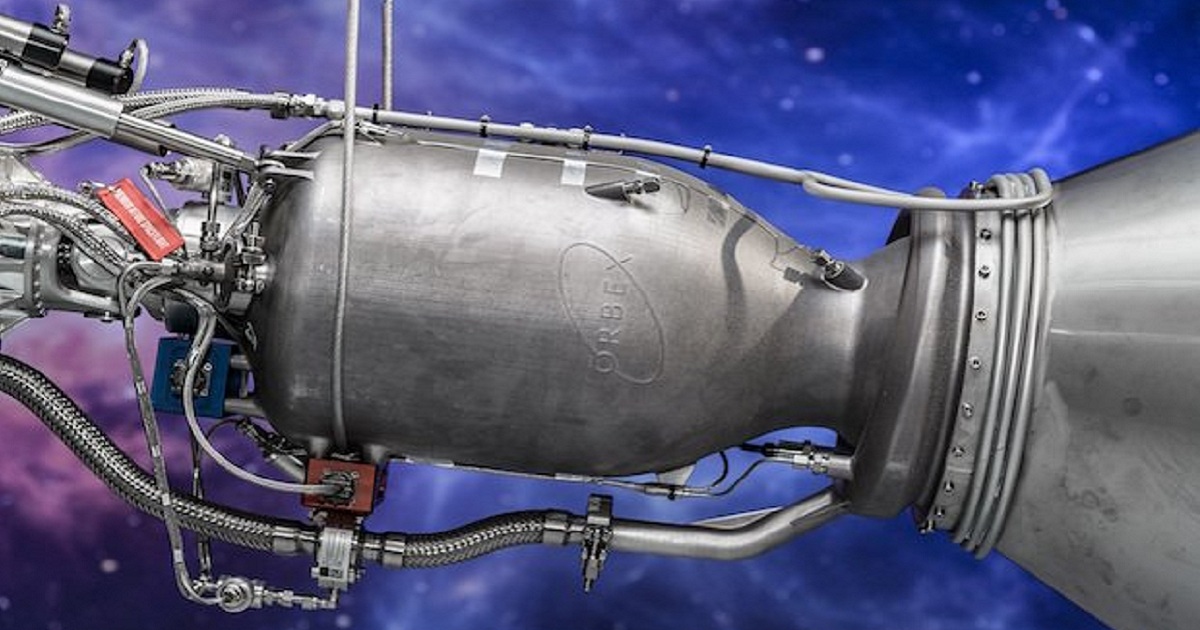

Orbex additively manufactures single piece rocket engine on SLM Solutions SLM 800

Orbex | February 11, 2019

Orbex, a UK-based spaceflight company, has 3D printed a rocket engine in a single piece on SLM Solutions SLM 800 metal additive manufacturing platform. The engine has been designed for the company’s environmentally friendly Prime rocket which was introduced at the opening of Orbex’s new headquarters in Forres, Scotland.

This rocket uses 100% renewable fuel helping to cut carbon emissions by around 90% and also boasts zero-shock staging and payload separation which results in zero orbital debris, according to Orbex. Its design optimized for the SLM process, engineers also managed to produce a structure that is 30% lighter and 20% more efficient than other engines in the same category of a launch vehicle.