How Cummins is using 3D printing to transform manufacturing

REMEMBER when 3D printing was making waves in the world of manufacturing as the most promising technology? Well, it seems 2019 will be the year that it actually gains momentum, moves past prototypes, and hits scale.

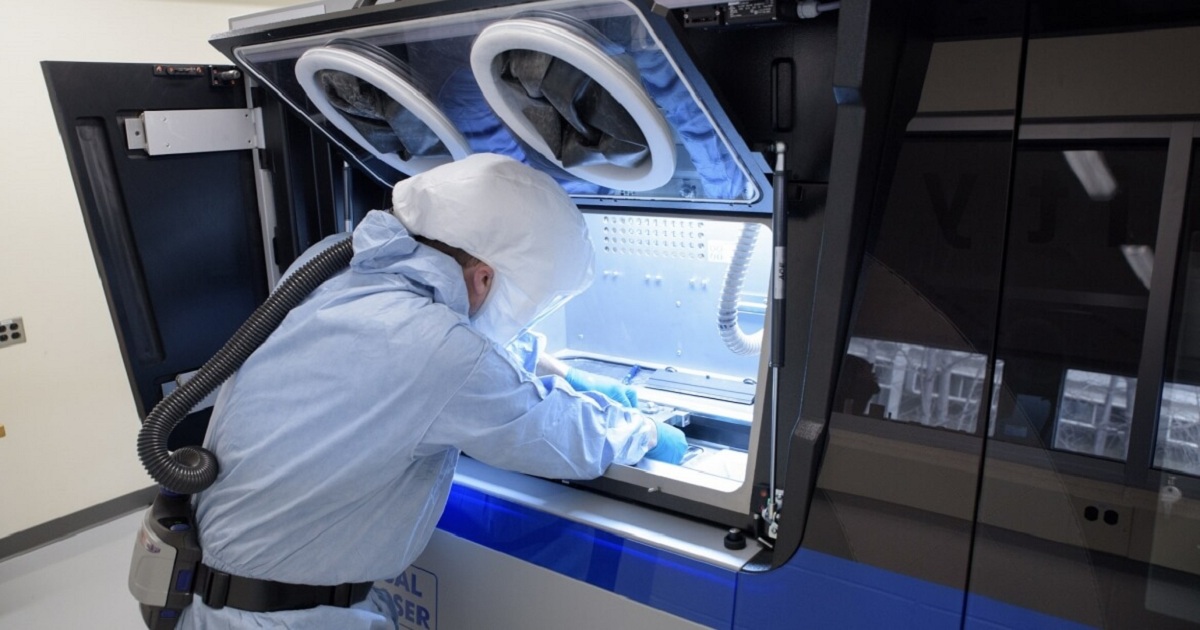

Cummins recently announced that it has sold its first ever metal part printed on one of its own 3D printers, moving the company a step closer to additive manufacturing - from theory to practice. This is an exciting event in the manufacturing industry because the company’s use case was precisely what experts said it should be: producing items with low volume demand.

Imagine, for instance, you own a 1956 Shelby Cobra 427 Roadster that you recently bought at an auction in Arizona, USA for US$1.5 million. It’s in mint condition but needs a new steering wheel emblem because the original one was damaged while being shipped to Singapore. That’s the sort of requirement 3D printing can help solve in the short run.