Ford automates design of 3D printed production tools with trinckle

Ford Motor Company | December 11, 2018

Ford is partnering with a Berlin-based software company, trinckle in order to automate and scale the design process for 3D printed production and assembly tools.

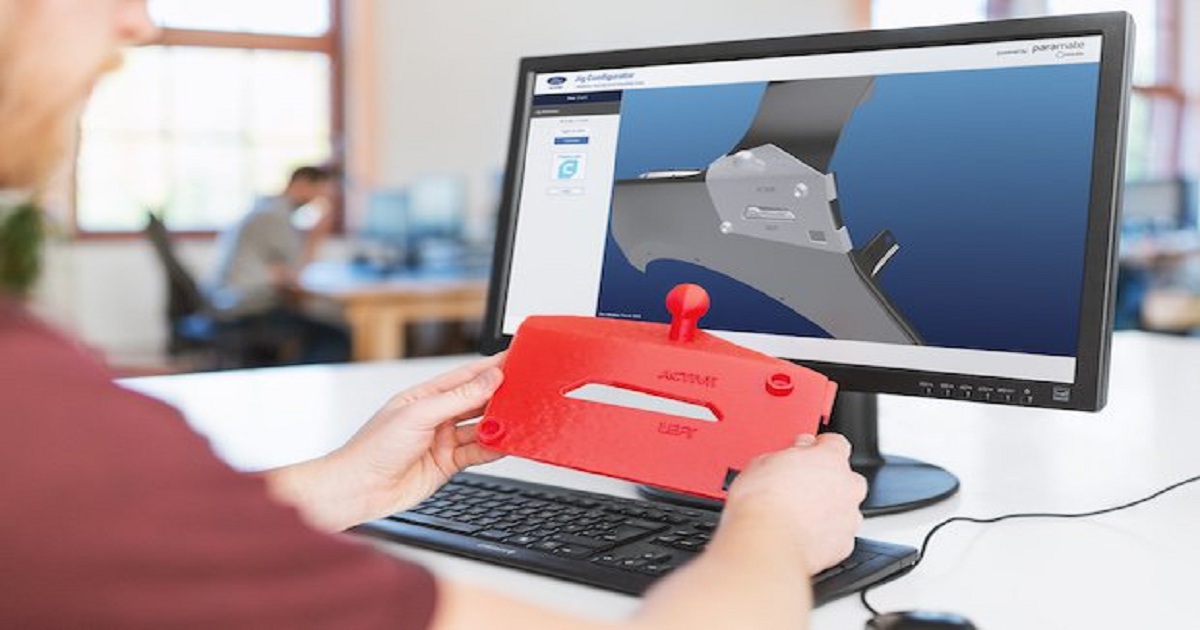

Using its paramate cloud software, trinckle develops software applications for the automated design of AM products. For Ford, which currently uses more than 50 different additive manufactured tools in serial production, trinckle developed an internal application for the efficient generation of labeling jigs, a hand tool used to place model badges on the body of the vehicle. Within the software, the user simply uploads the model data of the car body and the badges to be placed along with additional elements such as handles, magnet mounts for fixation, edge guides, and text fields. Paramate’s algorithms then automatically generate the geometry of the tool to fit the contour of the car body.