Betatype doubles the production of metal orthopedic implants

Betatype | January 10, 2019

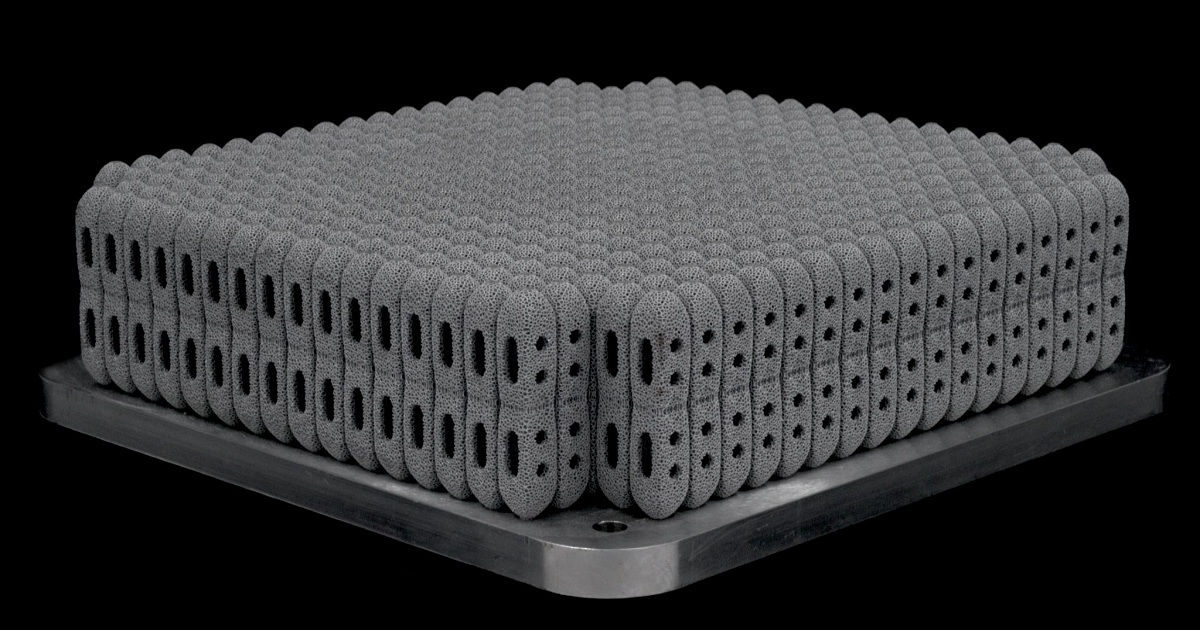

Betatype, a London-based additive manufacturing software company has released a case study showing that its software can double the production of 3D printed metal orthopedic implants. This is done with the help of Engine, a 3D printing workflow optimization software by Betatype which generates small-sized data files for efficient processing.

A case study, using Renishaw‘s RenAM 500Q powder bed fusion (PBF) printer Betatype shows how Engine realizes the potential of the metal printer to make orthopedic implants. Models like orthopedic implants often have a complex geometrical structure. When orthopedic models are sliced for metal 3D printing, process parameters such as laser scanning path, laser power, and spacing are generated.