BASF launches Ultrafuse 316L metal 3D printing filament

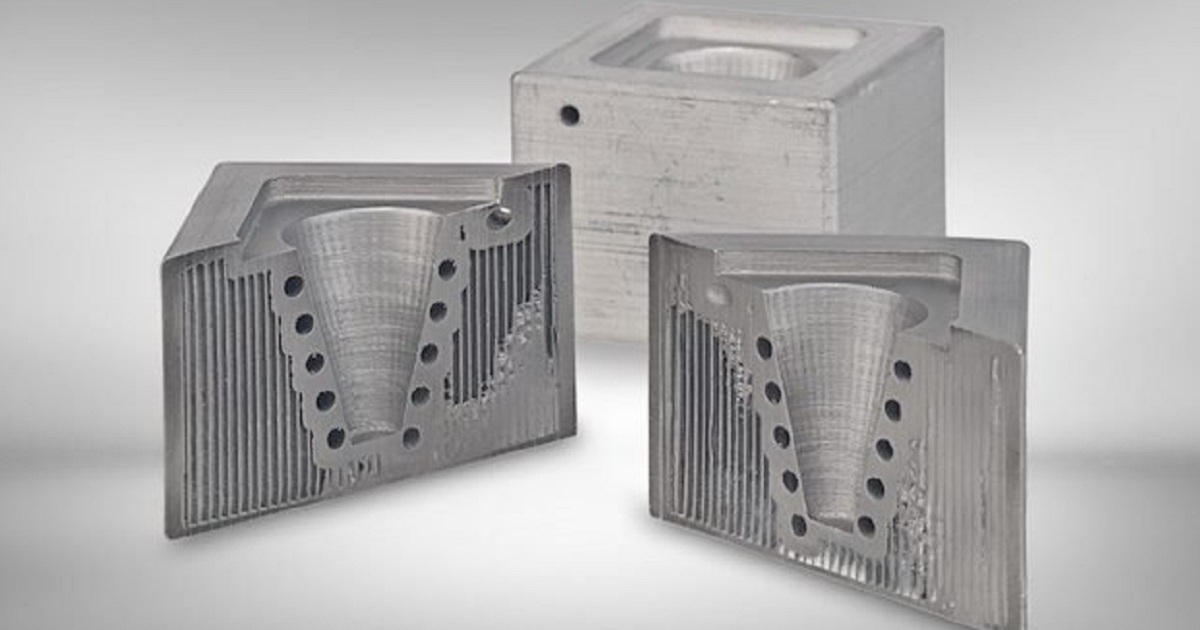

The additive manufacturing arm of global chemical company BASF has formally launched its metal-polymer 3D printing filament onto the market. First introduced last year, Ultrafuse 316L is said to enable simple and cost-efficient production of full metal prototypes, tooling and end-use parts using any extrusion-based 3D printer. Parts can be printed on a suitable printer in a similar fashion to that of a standard plastic extrusion process to create a so-called green part. The part then goes through an debinding and sintering process to remove the binder and leave a solid 316L stainless steel product. Ultrafuse 316L is made up of approximately 90% metal content with a mix of polymer particles which act as a binder. BASF says the material's high metal content and even distribution within the binder matrix reduces the risk of defects, while the immobilisation of metal particles in a filament form reduces potential hazards compared to metal powder-based processes such as selective laser melting SLM or direct metal laser sintering.