3D printing smarter with machine learning

Today's Medical Developments | February 24, 2020

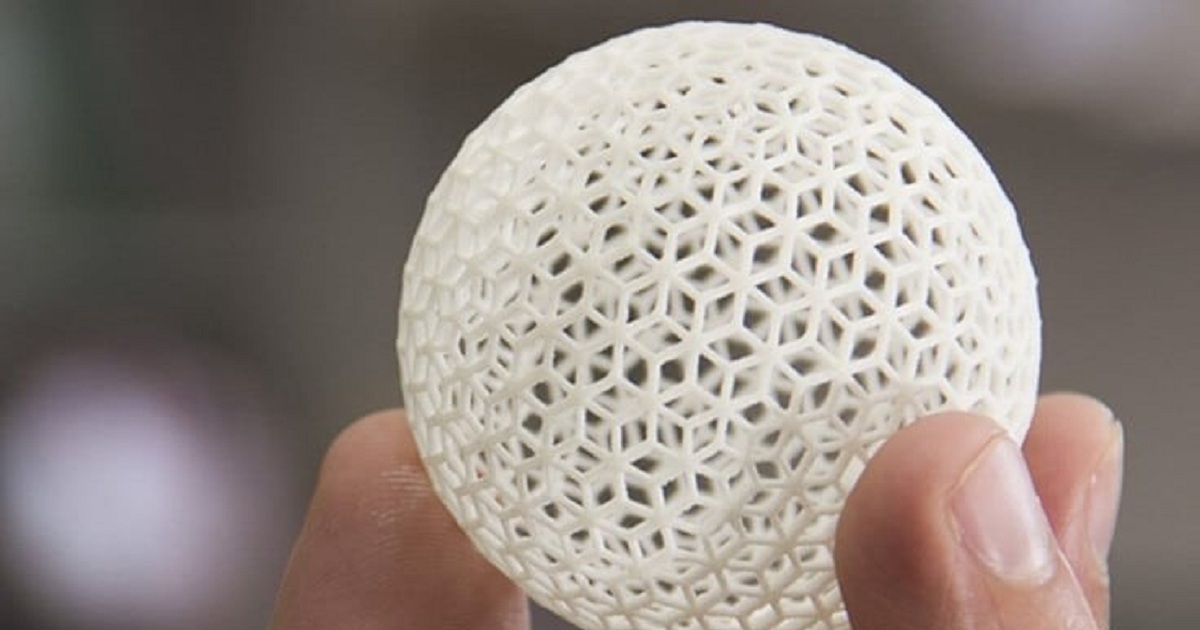

3D allows objects from computer-generated designs to be directly built, but 3D printing can have a high degree of error, such as shape distortion. Each printer is different, and the printed material can shrink and expand in unexpected ways. Manufacturers often need to try many iterations of a print before they get it right. A team of researchers from the Daniel J. Epstein Department of Industrial and Systems Engineering tackled the problem with a new set of machine learning algorithms and a software tool called PrintFixer, to improve 3D printing accuracy by 50% or more, making the process vastly more economical and sustainable. The result of six years of research, the work, recently published in IEEE Transactions on Automation Science and Engineering, describes a process called convolution modeling of 3D printing.