3D printing and robots power largest furniture maker in the world

Ashley Furniture | May 22, 2019

Ashley Furniture is the largest furniture manufacturer in the world. Traditionally, the company has been subject to the whims of labor markets. But a forward-thinking approach to automation that relies on robots and 3D printing technologies has helped the family-owned company thrive in a shrinking labor market.

We're doing 10% more business out of our Arcadia facility alone with probably almost 15% less labor, said Vaughn Pieters, senior director of casegood operations. Automation has really allowed us to remove some of that heavy physicality that manufacturing has had the stigma of over the last 50 to 60 years. We don't have employees doing that heavy bulk work all day long anymore.

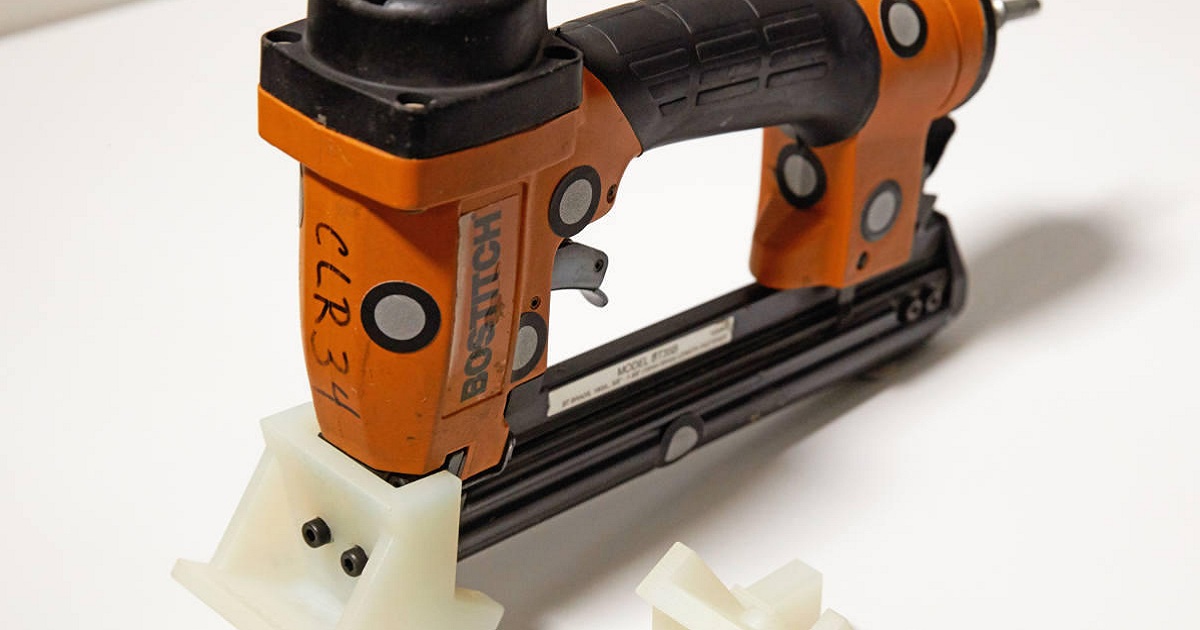

Ashley installed its first robot on the manufacturing floor five years ago, making it a slow entrant to the industrial automation game. But it's since taken a flying leap into robotics, and by leaning into 3D printing to help retool its manufacturing line, Ashley has expanded its automation footprint while sidestepping traditional constraints of industrial automation, such as minimum orders and long retooling times.