Prime Time for Additive Manufacturing

Supply Chain Management Review | March 05, 2020

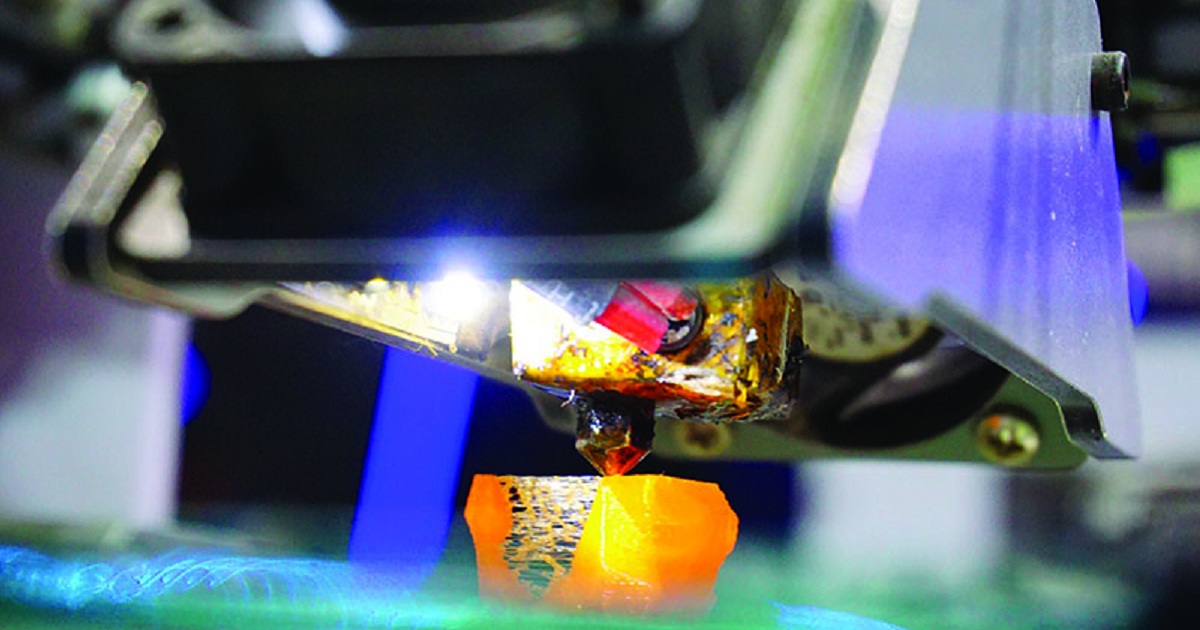

Disruption is the rule in supply chain management and manufacturing today. Although conventional supply chains remain the backbone of global commerce, most observers expect convention to make way for fundamentally new processes such as manufacturing on demand that involve additive manufacturing and 3D printing. That’s certainly our conclusion based on our research for this article, which included field studies of the customers of Fast Radius, a Chicago-based AM solutions company. Utilizing in-depth interviews with key personnel and a review of secondary sources, we’ve put together a best practices framework along with insights for supply chain managers who are considering AM in the context of their digital supply chains. The story of additive manufacturing is similar to other disruptive innovations that made the leap from the fringe to the mainstream, such as the Internet, electric cars and social sharing platforms like Uber and Airbnb. While AM has a nearly 40 year history, it’s now poised to make that transition over the next decade. Capabilities and case studies continue to grow as the drawbacks to AM such as time, cost and material availability, continue to shrink. Forward-thinking companies such as GE, Seimens and Wassara are already reaping the benefits of AM.